Project Description

Hydraulic-Guillotine-Shears-DA310s YSDCNC

Main Features:

Streamlined design originated from EU, main structure consists of rack, cutter holder, oil cylinder, hydraulic controller, backgauge and other components. Finite-element analysis of main parts, Welding parts uses tempering, vibration and other processing methods to eliminate stress ensuring the structural strength and rigidity of each component;

Cutter holder use three-point support rolling guide rail, reducing the friction to the greatest extent, and realizing seamless rolling during cutter holder moving.

Leftmost front holder configured with verticality regulator and front positioning device, easy operation and high efficiency;

Simple and effective blade adjusting mechanism rearranges blade clearance by CNC system, improving the cutting quality.

Through fine ball screw and polished rod structure, good-performance servo motor control X-axis to ensure the accuracy, and unique designed timing transmission mechanism to ensure operation stable and reliable;

Light and shadow line is conductive to manual scribing for cutting; stable and reliable hydraulic transmission; integrated hydraulic system is able to significantly reduce problems caused by hydraulic fluid leakage;

High-quality alloy tool steel is capable enough to against impact load and high wear resistance when cutting;

Referring to ergonomic design, user-friendly operation interface, improving the operation precision and comfortability;

rolling ball workbench to reduce friction and prevent work piece surface from scratching;

unique and practical safety guard, line with safety specifications, protect the personal safety; exquisite design, petty work piece can be done easily by hand.

Easy installing, NO need any professional electrician skills

Just fix the screws on the ground and connect to power supply

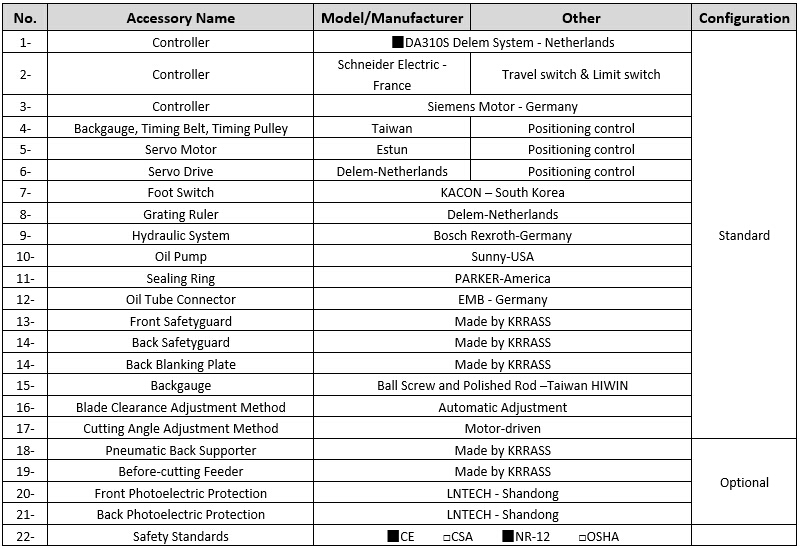

Standard Configuration:

Netherlands DELEM DA310S CNC controller

Backgauge X-axis is driven by servo motor

Servo motor drives controller

HIWIN ball screw and polished rod, control accuracy of 0.05mm.

Controller cantilever and front supporter

Germany Bosch Rexroth integrated hydraulic valve

Germany EMB oil tube connector and high-pressure hose

Germany Siemens main motor

France Schneider electrics

Hydraulic and electrical overload protection

Light aligning

Blade materials ( Cr12MoV )

South Korea KACON foot switch

Blade clearance is adjusted automatically

Safety Standard

Safety standards ( 2006/42/EC )

The electrical cabinet and the front safeguard door open to power off

Domestic pedal switch (safety grade 4)

Rear metal safeguard rail, CE standard

Safety relay monitors pedal switch, safety protection

Netherlands DELEM DA310S NC Controller:

High-definition LCD display, 128X64 pi

Backgauge control

Cutter clearance control

Cutting stroke control

Synchronously display the actual position and programming

Cutting count

100 programs

Servo control

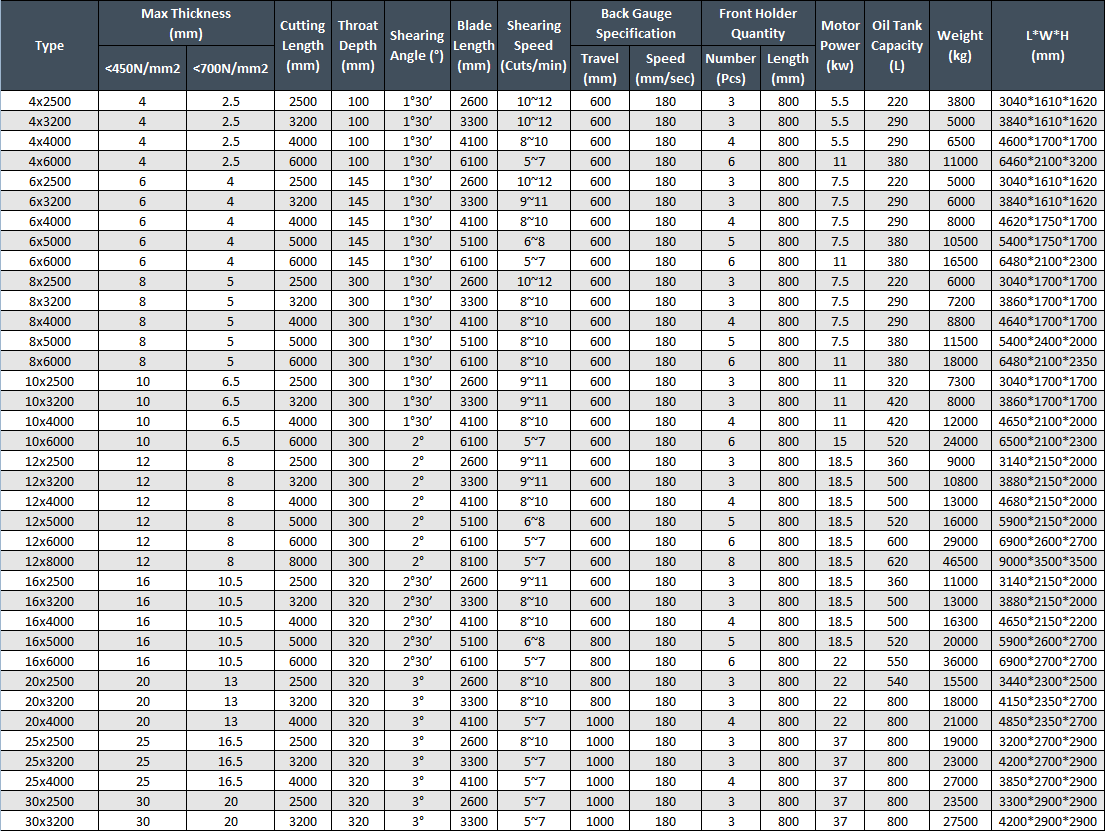

Technical Paremeter

HTML Forms powered by Wufoo.